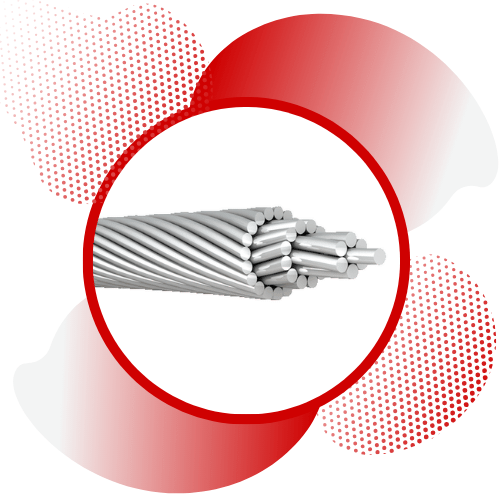

AAC Conductor

AAC (All Aluminium Conductor) is a type of electrical conductor made entirely of aluminium strands. It is primarily used in overhead power transmission and distribution lines, especially in areas where high conductivity and lightweight construction are required. AAC conductors are known for their excellent corrosion resistance, making them suitable for coastal and humid environments.

Description

Laser AAC conductors consist of multiple strands of hard-drawn aluminium and comply with standards such as IS, ASTM, BS EN, DIN, IEC, and NFC. These conductors are widely utilized in low, medium, and high-voltage overhead power lines. They are particularly preferred in urban areas where shorter spans require high conductivity. Additionally, the excellent corrosion resistance of aluminium makes AAC conductors ideal for use in coastal regions.

Characteristics

Made from high-purity hard-drawn aluminium

High electrical conductivity for efficient power transmission

Lightweight and easy to handle

Eco-Friendly: Fully recyclable, contributing to sustainability

Technical information

| Parameter | Specification |

|---|---|

| Conductor Material | 99.5% or higher purity aluminium |

| Voltage Rating | Low & Medium Voltage Distribution Networks |

| Core Configuration | Single or multi-strand aluminium wires |

| Operating Temperature | Up to 75°C (Normal), 150°C (Short Circuit) |

| Tensile Strength | Lower than ACSR, suitable for short-span applications |

| Current Carrying Capacity | High, due to pure aluminium composition |

| Corrosion Resistance | Excellent, making it ideal for coastal and industrial areas |

| Weight | Lightweight compared to ACSR and copper conductors |

| Application | Overhead power distribution, urban areas, and coastal regions |