AAAC Conductor

The All Aluminium Alloy (AAA) Conductor is a high-performance overhead conductor used in power transmission and distribution. Made from an aluminium-magnesium-silicon alloy, it offers superior strength, conductivity, and corrosion resistance compared to All Aluminium Conductor (AAC). Its lightweight nature makes it an efficient alternative to Aluminium Conductor Steel Reinforced (ACSR), allowing for longer spans and reduced infrastructure costs. With excellent resistance to environmental degradation, it is ideal for coastal and industrial applications. AAA conductors ensure efficient power distribution with improved conductivity and minimal power losses, making them suitable for medium and high-voltage networks.

Description

The conductor consists of Aluminium Magnesium - Silicon alloy wires stranded in successive layers in opposite direction and the outer layer is in the right hand direction Z. In case required, neutral grease shall be applied between the layers of AAAC except the outer layer.

Standard

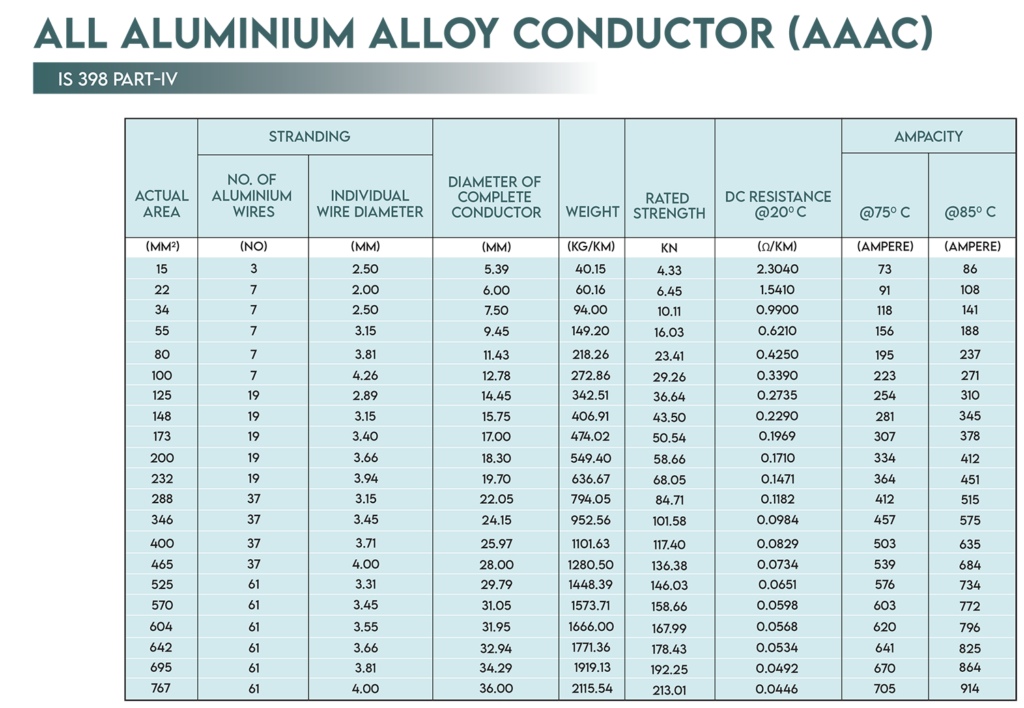

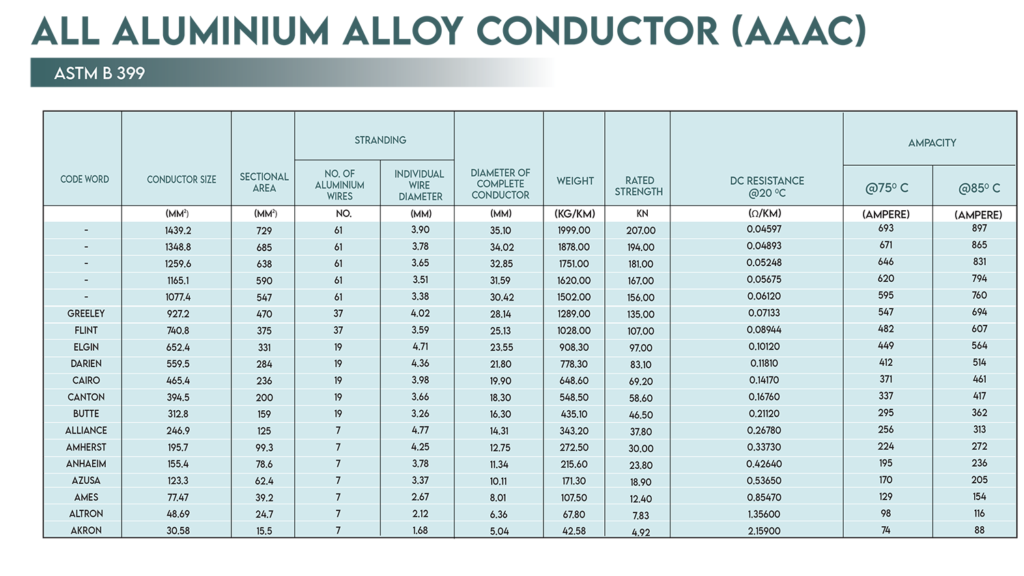

The construction is done as per IS 398 part 4, EN 50182, ASTM B399, IEC 61089 and other International Specifications. The requirement/specifications given by the purchaser are also taken care of.

Advantages

AAAC exhibits excellent corrosion resistance especially in sea coast areas and in polluted industrial areas due to absence of steel core.

The surface hardness of AAAC is 80 BHN as compared to 35 BHN of ACSR.

AAAC are stable up to 90 C against ACSR conductors which are stable up to 75 C.

AAAC can carry at least 15-20% extra current as compared to ACSR of equal size.

The surface hardness of AAAC is 80 BHN as compared to 35 BHN of ACSR.

This reduces the damage to surface during handling and therefore leading to lesser corona losses and ratio interference at EHV.

Applications

A.A.A.C. are mainly used for overhead lines, in transmission and distribution electrical networks, having relatively long spans. They are also used a messenger to support overhead electrical cables.

Description

The conductor consists of Aluminium Magnesium – Silicon alloy wires stranded in successive layers in opposite direction and the outer layer is in the right hand direction Z. In case required, neutral grease shall be applied between the layers of AAAC except the outer layer.

Standard

The construction is done as per IS 398 part 4, EN 50182, ASTM B399, IEC 61089 and other International Specifications. The requirement/specifications given by the purchaser are also taken care of.

Characteristics

Strands of same diameter in Aluminium- Magnesium-Silicon group alloys, duly heat treated.

Has almost double the tensile strength of pure aluminium strands and thereby are ideal for long spans.

Suited as an alternate to ACSR or AAC depending on line engineer needs.

Low electrical losses compared to ACSR.

Superior corrosion resistance.

Ideal for seacoasts, saline and corrosion prone areas.

Suited for developing countries in order to avoid pilferage & thefts.

Application

AAAC bare conductors are used for primary and secondary overhead power transmission lines having long spans and high resistance to corrosion.